When it comes to installation of Heat Pump (or Solar Thermal) Systems, one of the key decisions our

customers have to take is whether they should go for direct or indirect integration of the Heat Pump (or

Solar Thermal) system with the existing heat generation system (eg. Diesel Boilers). The obvious advantage

of an indirect process heat integration is that since there is no mixing of fluids, maintenance is easy.

However, the downside is that it is more expensive. Before getting into more details, let us look at what a

direct and an indirect integration means.

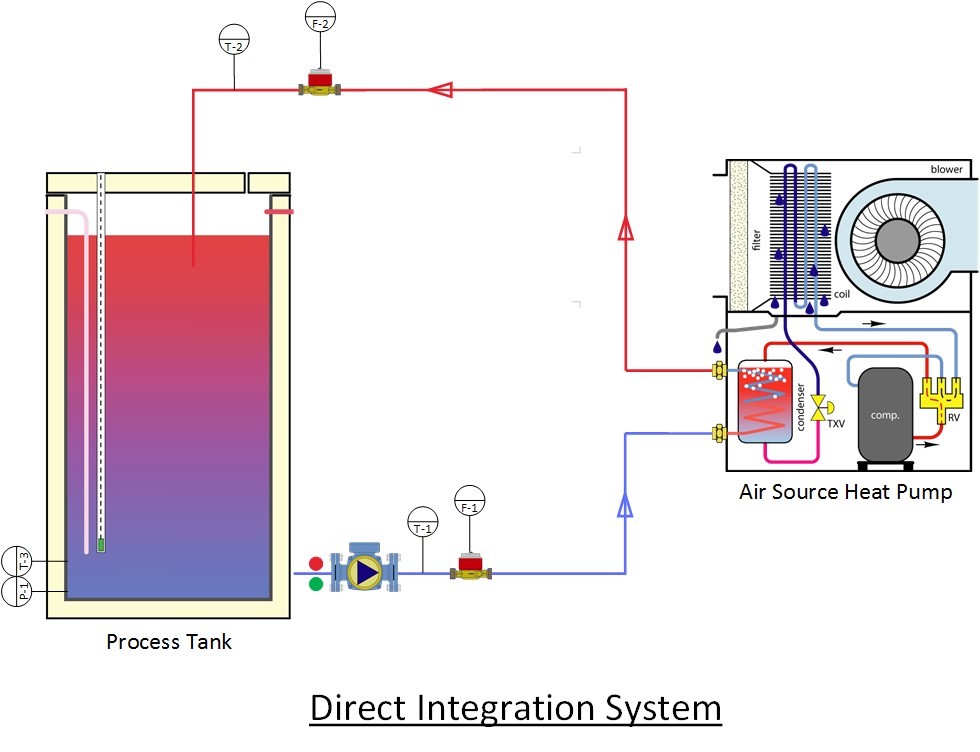

In a direct integration system, the heat transfer takes place between hot and cold fluids. There are no

separating walls between the fluids. Properties of process fluids such as viscosity, thermal conductivity,

specific heat reaction on the metal in contact are essential to determine the pumping thermal requirement

and material of construction.

Even though the direct integration of a heat pump with process tank looks simple and has higher efficiency,

the cost-effectiveness depends on the type of process that requires heat.

For example, the hot water generation through direct integration of a heat pump with centralized hot water

storage tank in hotels will have more cost benefits than the pre-treatment applications in manufacturing

industries. Because in the pre-treatment process, the acidic and alkali solutions are used to treat the metal

components by dipping it through a series of process tanks. These solutions are corrosive and colloidal in

nature requires stainless steel of higher grade as the material of construction for piping components and heat

exchanger.

In hotels, only raw water is used as a heating medium, which is not corrosive, and scale formed by dissolved

salts in raw water can be easily cleaned periodically with suitable inhibited acids. However, for using direct

integration in a pre-treatment process application, the maintenance cost for frequent cleaning of heat

exchangers, strainers and filters will overshoot the indirect integration cost down the road.

The direct integration is best suited for hotels, canteens and some industrial applications where raw

water/RO water needs to be heated.

Some of the advantages and disadvantages of direct integration system are listed below:

Indirect process heat integration

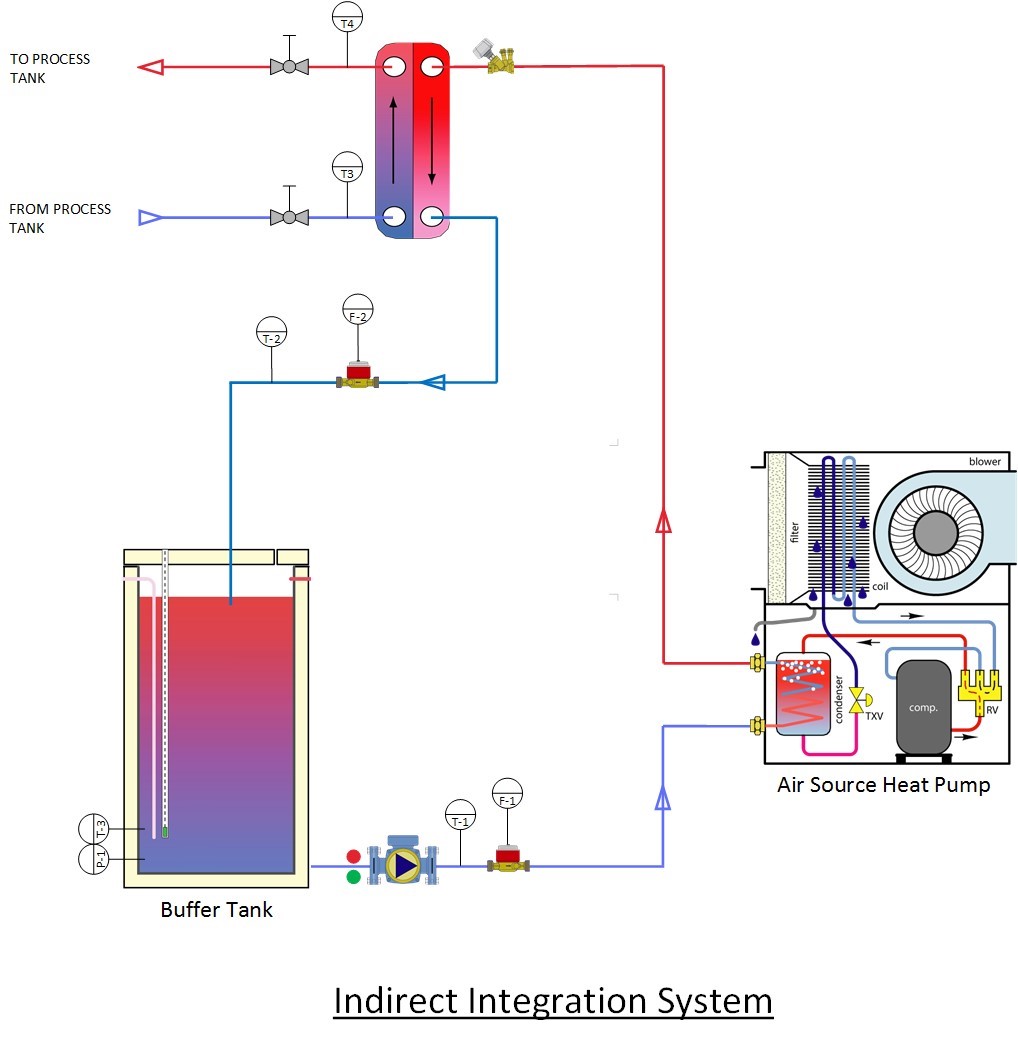

In an indirect integration system, the heat transfer takes place continuously from the hot fluid to the cold fluid through a dividing wall. Properties of process fluids such as viscosity, thermal conductivity, specific heat reaction on the metal in contact are essential to determine the pumping thermal requirement and material of construction.

Indirect process heat integration differs from direct process heat integration in that an intermediate circuit is used for transferring heat between the two process streams. The transfer medium (water) absorbs heat in one part of the plant and releases it in another. This approach is used when:

- Direct contact between heat source and heat sink is not allowed. The intermediate circuit works as a safety barrier and leakages can be detected in the loop, before the process fluids mix.

- Process heat is supplied from long distant Centralized Heating System.

- Flexibility and reduced interdependence is required. Equipping the intermediate circuit with standby coolers and heaters makes it easier to disconnect a unit operation for maintenance, avoiding interdependence between plants.

- One heat sink requires multiple heat sources.

- Indirect process heat integration opens up a vast range of possibilities. Some common applications are:

- Heating Pre-treatment tanks (Surface Cleaning and Coating Process Tanks)

- Component Washing Application

- DG Pre-heating system

- Any Multi-tank centralized heating system.

Indirect Integration is significantly more expensive in the beginning, but safer and less costly in the long run. Some of the advantages and disadvantages of indirect integration system are listed below:

Conclusion

Because of the number of technical and practical constraints in integrating Air/Water Source heat pump with existing heating system, the notion of this talk is to understand all economically and technically feasible opportunities for direct/indirect integration system and then compare them to select the optimal integration solution. The selection of integration type primarily depends on the properties of process fluid and number of tanks to be integrated. Here are some of the common applications that requires heat with best-suited integration system:

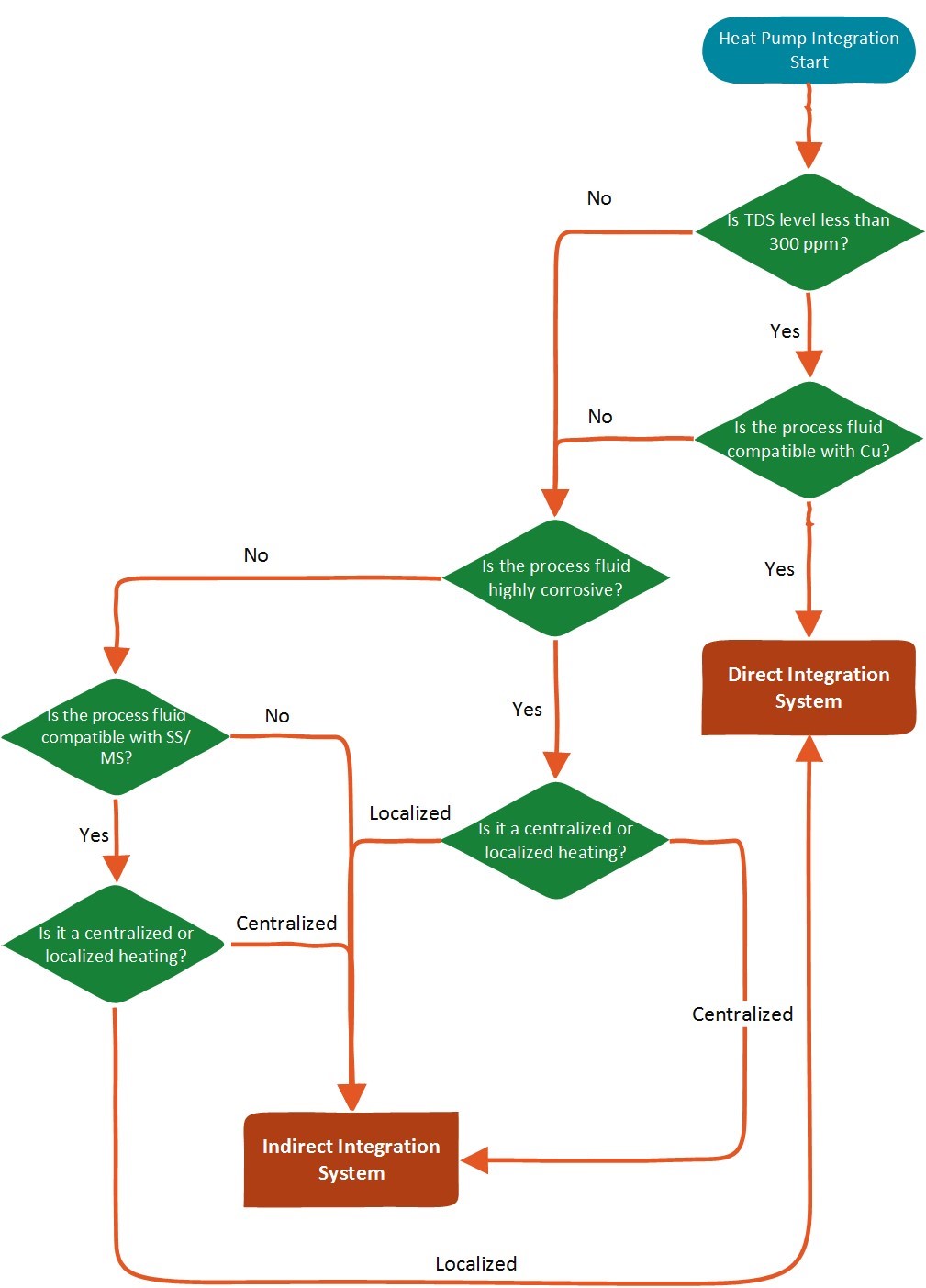

The following flow chart will give brief idea on selecting proper integration system for heat pump:

Integration Flowchart